I did not know that the 4200 report monitor is capable of producing an almost holographic image. The quality at 7,5ips is quite remarkable with 18hz to almost 26khz quite respectable to say. I have completely rebuild (and changed in certain stages) the 4200 report monitor. On the other hand, if it is one of the reel drums, it is quite an operation to reach them.

I hope it's not your motor that needs lubrication. touch the brass flywheel when the motor is running if the horrible noise changes. Remove the capstan and put the machine on its back side. If I'm right you only have to remove two screws but it could be possible that the capstan plate is holding another little board that needs support: unscrew it. If the noise is still not gone: Open her up and remove the flywheel plate. It is also possible that your counter is making this horrible noise: remove the belt. If the noise doesn't stop, there is a little roller on the left (which is actually the brake and tension in one) move it towards the heads. stop the right reel drum with your fingers. I assume the horrible noise is not there when you power on, machine is in stop position.Īlso I assume that you have checked the pinch roller. The horrible noise: Power on the machine at the highest speed without any reels loaded. I expect you have replaced the belts ? Two on the motor, one on the counter, right ? Also never use oil with these machines on any place else then the capstan bearings (these are rotating, in copper covered, use just one tiny drop from a needle) Rubber normally doesn't go bad in these machines as long as you do not use cleaner, solvents. Voltages over 25 VDC can kill you, and should be safely discharged before you touch any metal. Before working on tube circuits, read the "HV safety for newbies" thread at the top of the tube forum here. Next time you see Wallace or Grommet, ask whether Electronics for Dogs is really that good. I already knew about tube circuit repair from "Electronics for XXXDogsXXX Scientists" a 1968 text I received in a college lab. Sixties transistor texts have a lot of calculations in them nobody does much anymore. They may have different useful texts at the community colleges near you. I learned a lot about modern electronics from a community college text I found at the charity resale shop, Thomas Floyd, "Electronic Devices, the electron flow version".

My Sony TC250 I was using as a preamp for the turntable got strange, and has about 100 electrolytic caps in it at $.50 each average, so I worked over a disco mixer instead. Besides the rubber, the electrolytic caps dry out and affect sound and volume. I've got three really nice sony's waiting to be worked over. The supply of replacement rubber parts is either a black art or something, except someone suggested one of the semi-pro Teac recorders was still supported. Old tape players are difficult to repair because the rubber dries out and acts differently, even if it doesn't crack. I think you are talking about a tape player or recorder, as Uher doesn't sell in my area. Do they blow (I can't see any that have) or are there more insidious faults that require replacement? If so, what are their symptoms and what should I replace them with? The boards don't seem to have any dry joints.Īs it's almost working it seems a shame to send it off to a repairman when I'm rather keen to do it myself, so DIY suggestions please! I've heard bad things about the capacitors too. Good enough for one evening though! I wondered if any of you had experience with these no doubt common issues for a machine of this age and had some tips 'n' tricks.

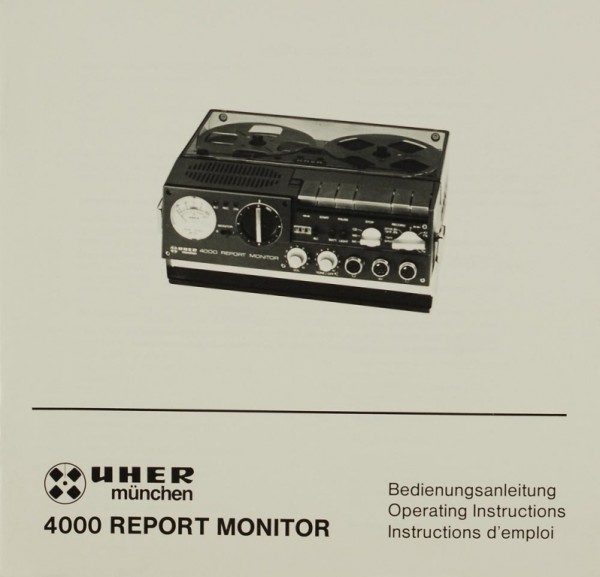

#UHER 4000 REPORT MONITOR MANUAL MANUAL#

Should I replace the rubber bits, try 'rejuvenating' all of them or go over it all with some kind of cleaner? I've adjusted the see-saw with the aid of a service manual but something's still not quite right. However when rewinding it sometimes finds it hard to get over the tape's resistance and makes a noise like the wheel's not entirely round and is gripping at one stage of the rotation but not the other. I can't see cracks and overall it doesn't give the sense of being dried out and perished. I've taken some of the rubber pieces off the forward/rewind 'see-saw' and they're still squishy and black. However it still has an intermittent squeal which I think has something to do with the drive wheels. I've fixed the start button and checked the belts, it plays, changes speed, fast forwards and rewinds.

It had a horrible squeal and a start button that wasn't sticking. I've just got a Uher 4000 Report-L from my Grandfather and various cables.

0 kommentar(er)

0 kommentar(er)